1. Skateboard Bearings: General Info

In order to keep your wheels rolling smoothly, you’ll need sensible Bearings.

Every skateboard wheel is equipped with two bearings. If you want, you can fill the space between them with a spacer. This small metal cylinder prevents the bearings from being forced into the centre of the wheels when tightening the axle nut and getting damaged. Furthermore, spacers ensure that your bearings remain parallel with each other. Spacers are particularly prudent if you have soft wheels or so-called “non-core wheels”.

The bearings you’ll find in the skatedeluxe Skate Shop fit in every standard wheel and work with every standard axle. When choosing your bearings, therefore, you don’t have to worry about the size.

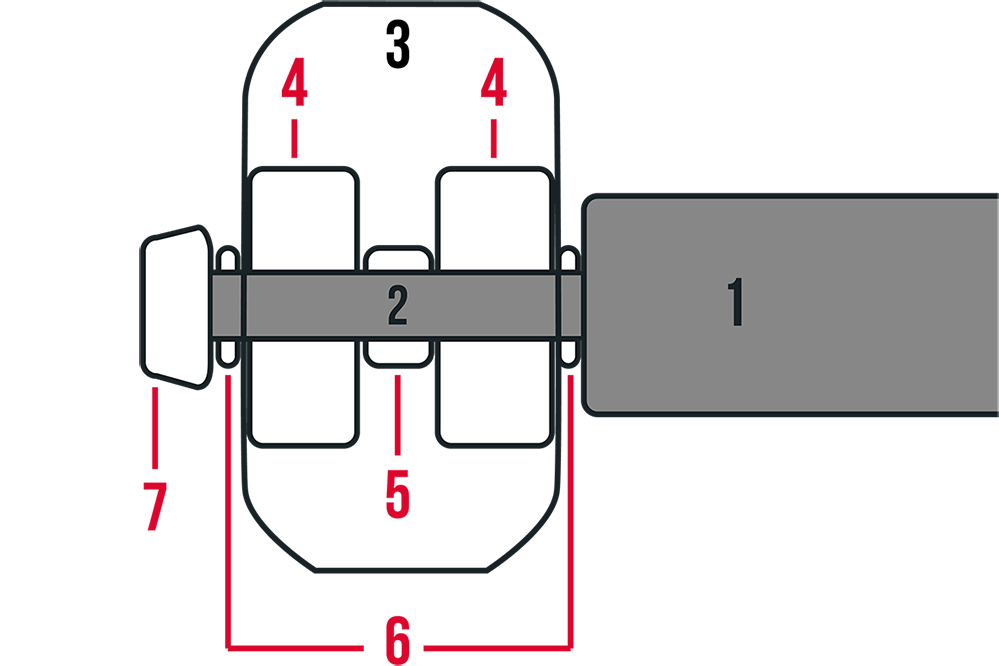

Where exactly do the bearings sit in the wheel?

1. Hanger

2. Axle

3. Wheel

4. Bearings

5. Spacer

6. Speed Ring

7. Axle Nut

1. Hanger

2. Axle

3. Wheel

4. Bearings

5. Spacer

6. Speed Ring

7. Axle Nut

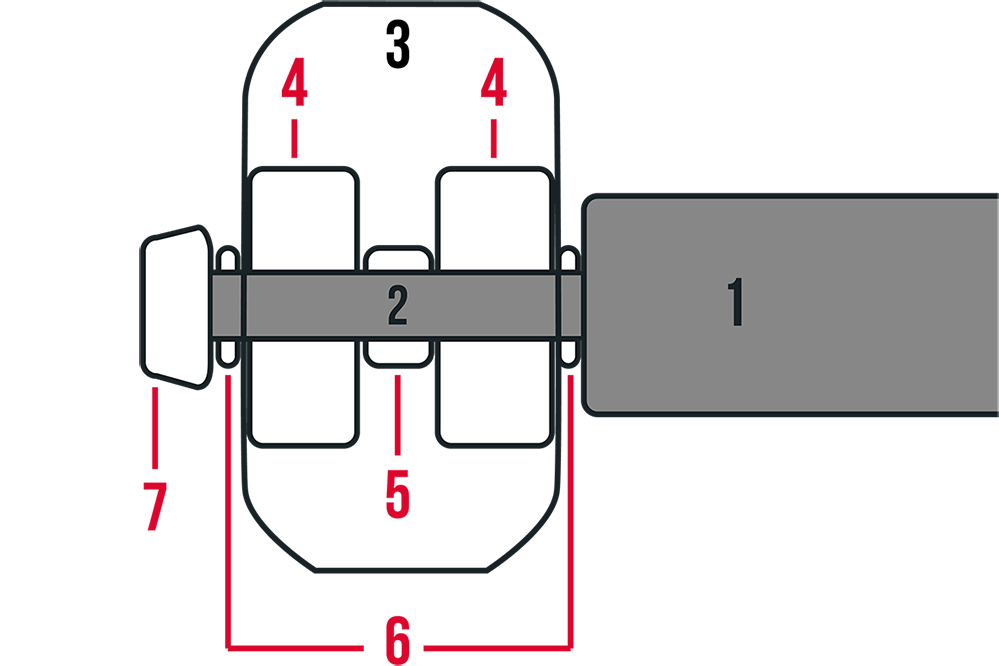

2. Skateboard Bearings: Composition & Parts

Bearings are comprised of a large outer ring and a smaller inner ring. Between these rings are small steel balls. These are what enable the wheels to turn. On either side of the rings are covers, called shields, which prevent the bearings from getting dirty. In order to keep the balls in position, they are contained inside of a so-called “ball cage.”

1. Outer Ring

2. Inner Ring

3. Ball Cage

4. Balls

You can also choose to skate with ball bearings without shields, which are open or semi-open. If you do skate with open or semi-open bearings, they will indeed be more susceptible to contamination, but they will be somewhat faster. Many skaters enjoy the slightly louder sound of a skateboard with open bearings.

1. Shield

2. Ball Cage

3. Ball

4. Outer Ring

5. Inner Ring

6. Shield

7. C-Ring

3. Fact or Myth? ABEC Rating as an indicator for high quality skateboard bearings?

„Dude, my ABEC 3 bearings are so lousy! It’d be so sick if I had ABEC 7s!“

The urban legend is that the higher the ABEC rating, the better and faster the bearings. But as is the case with most myths and legends, this one is for the most part nonsense.

The acronym ABEC stands for “Annular Bearing Engineers Committee,” and is a standard for how fine the rolling elements are. The higher the ABEC rating, the lower the tolerance for error in the manufacturing process. The rating does provide reliable information on the quality of the bearings. However, because the RPMs achieved when skating are so comparatively low, the rating is all but irrelevant. The full potential of a high ABEC rating would unfortunately never be reached because of the relatively low speeds achieved in classic skating.

To put it into more specific terms:

ABEC 7 or 9 bearings can reach 20,000-30,000 rpm at their full potential. For a 54mm wheel, this would correspond to a speed of over 200 km/h. For this reason, some manufacturers now renounce ABEC rating although it can still give a rough first impression of the quality of the bearings. As far as the relevance for skating and speed goes, the ABEC rating says quite little because skateboarding impacts bearings very differently than the traditional industrial uses.

For this very reason, we have “Skate Tested Bearings” or “Skate Rated Bearings.” These are usually more resistant and have been specifically developed to meet the demands of skateboarding; for instance, the impact on the bearings when landing tricks, or the lateral forces when turning.

There are, of course, always new and exciting developments in the realm of bearings. There are now skateboard bearings with parts made out of titanium or extra-hard balls made of tempered ceramic. These special technologies offer a longer lifespan and are naturally also more expensive.

4. Skateboard Bearings: Assembly & Removal

We’ll show you exactly how to mount your wheels on your trucks and how to get the bearings into your wheels in our Skateboard Assembly Instructions and in the comprehensive video below. Make sure that you don’t use excessive force when attempting to insert your bearings, as not to damage the wheel core or bearing.

How to get your bearings back out of your wheels

If your wheels are worn out, but your bearings are still in working order, you can get them out from your wheels in a few easy steps.

• Turn your deck on its side, so that the axel is pointing upwards.

• Loosen the axle nut and remove the top speed ring.

• Take the wheel off the axle, and slightly reinsert it at an angle. Like this, you should be able to pry the bearing from the wheel core.

• Make sure you don’t apply too much force, or you’ll damage the bearing. It will take a little muscle though.

5. Skateboard Bearings: Care & Cleaning

You can do your bearings and yourself a huge favour by following a few simple ground rules.

Skateboard bearing care – tips

- Water will cause your bearings to rust, so you should avoid ever letting them come into contact with water. So it’s best not to skate in the rain. It’s also better for your deck, not to mention the increased risk of injury of skating on wet concrete and ramps. Dust can also be a menace to your bearings.

- Never oil your bearings without having first cleaned.

How to clean your skateboard bearings

An important point when it comes to bearing care is maintenance. Cleaning your bearings extends their lifespan and often makes old bearings fast and smooth again.

To spruce up your skateboard bearings, you need the following:

- A cleaning container

- Cleaning fluid (e.g. brake cleaner or acetone, available in hardware stores)

- Lubricant or bearing oil

- Recommended: a drop cloth & gloves

If you don’t have a special cleaning container, you can also use a small bowl. We also recommend a drop cloth that can get dirty and some gloves. Attention: degreasing cleaning agents like acetone can be harmful to your health. Follow the instructions on the packaging and make sure there’s good ventilation in the room where you’re doing the cleaning. The following instructions will show you how to clean skateboard bearings using a Bones Cleaning container. Oil and cleaning containers for bearings can be found in our skate shop.

Instructions: cleaning skateboard bearings

-

Get the bearings out of the wheels

First, all bearings must be removed from the wheels. Simply lever them out with the help of your trucks’ axle.

-

Remove shields

Then carefully remove the rubber covers (shields) of the bearings (e.g. with a safety pin). Be careful not to bend or damage the shields.

-

Place bearings in cleaning container

Put the bearings onto the bolt in the lid. Put a spacer between each bearing. The balls of the bearings should point upwards, the cages should point downwards.

-

Add cleaning fluid & shake

Fill the container with cleaning fluid (the container doesn’t need to be full) and close it. Then shake for a few seconds. Allow the liquid to work for a bit.

-

Dry the bearings

Remove the bearings from the container and let them dry on a suitable surface. You can also carefully tap the liquid from the bearings.

-

Lubricate the bearings

When the bearings are completely dry, apply one to two drops of bearing oil per bearing. Hold the inner ring with thumb and index finger and turn the outer ring a little to distribute the oil.

-

Reapply shields

Finally, press the shields back onto the bearings and check for a straight fit. The bearings can now be mounted again.

Lubricant & Cleaning Containers

Don’t feel like reading all that? Get the most important information about skateboard bearings in this video!

Don’t feel like reading all that? Get the most important information about skateboard bearings in this video!